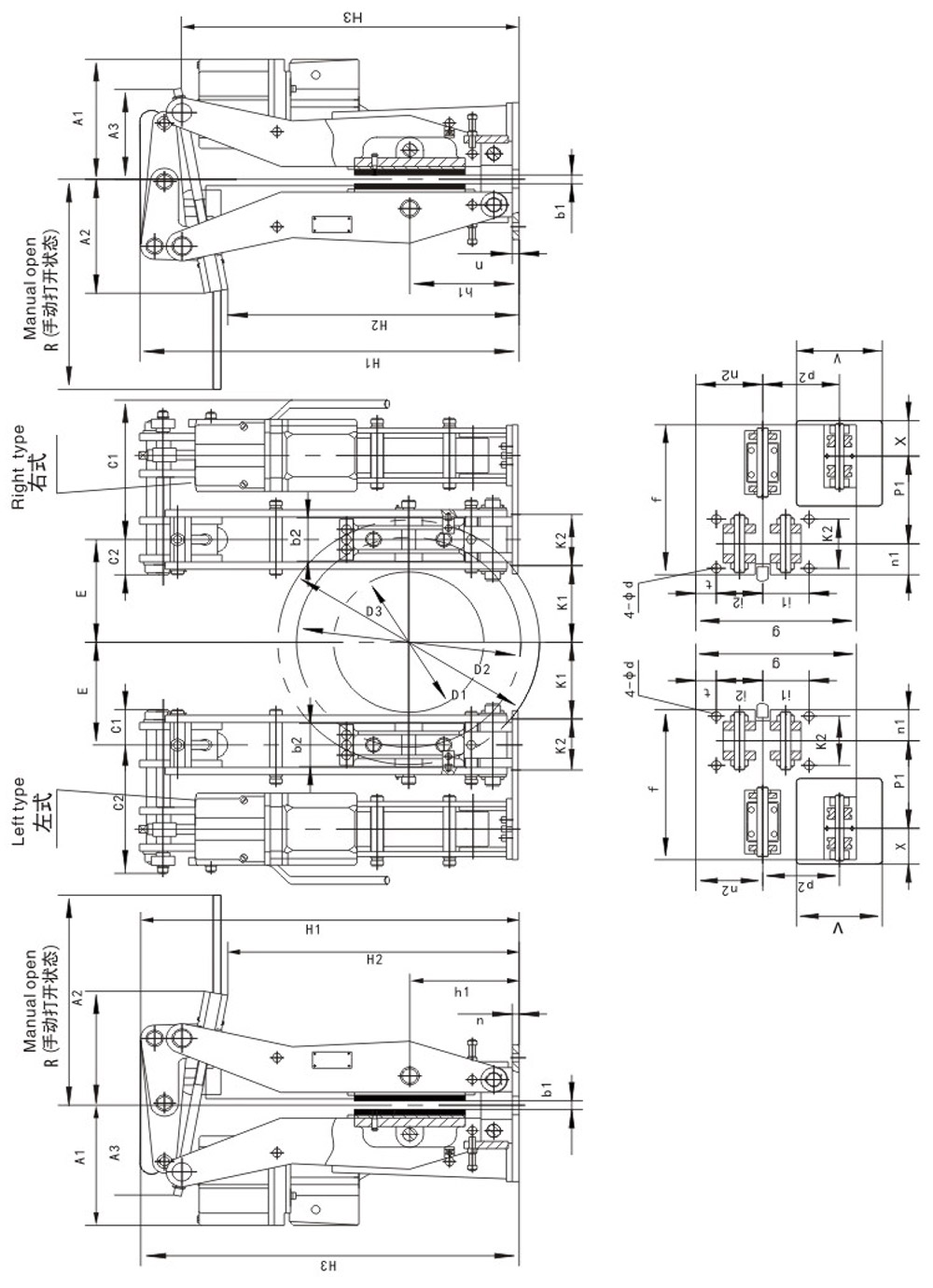

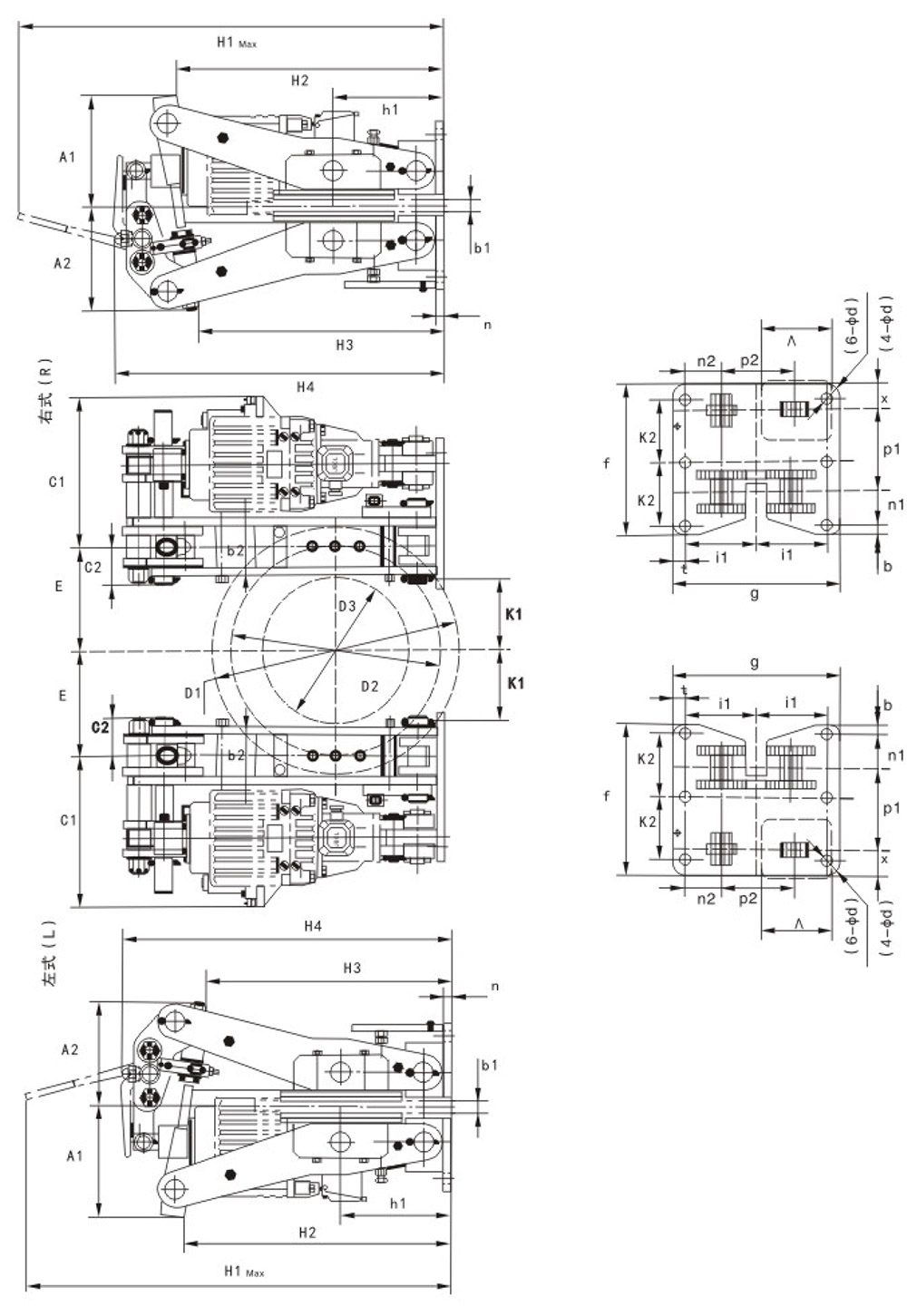

YPZ21I, Ⅱ and Ⅲ conform to DIN15435. YPZ2IV, V, and VI conform to DIN15435 and JB/T7020-2006.

Performance is safe and reliable, with smooth braking, high frequency of operation, and adjustable braking torque.

Major swing hinge points are equipped with self-lubricating bearings, ensuring high transmission efficiency without the need for lubrication during use.

The brake springs are arranged inside a spring tube, with a torque scale provided for intuitive display and easy adjustment of braking torque.

Insert-type brake pads: asbestos-free, safe, reliable, and easy to replace quickly.

Insert-type brake pads: asbestos-free, safe, reliable, and easy to replace quickly.

The brake can achieve delayed opening or closing by adding an ascent or descent valve to the actuator.

Additional functions can be implemented by equipping the brake with supplementary devices.

Automatic wear compensation device: allows for continuous automatic compensation of brake pad wear, adjusting the clearance and braking torque accordingly.

Opening or closing display switch: provides a signal display or interlocking protection to indicate whether the brake is functioning normally.

Wear limit display switch: signals or provides interlocking protection when the brake pads have worn to their limit.

Manual release device: enables the brake to be opened while the actuator is in a non-working state (for maintenance during power outages).

Ambient temperature:-20℃~50℃�。

The relative humidity of the air is not more than 90%.

The altitude of the site is in line with GB755-2008.

Flammable, explosive and corrosive gases are not allowed in the working environment. Otherwise, explosion-proof or anti-corrosion products should be used.

Power supply: three-phase AC 50HZ, 380V. (The company can provide other different frequency, different voltage products)

Work duty: S1,S3-60%���。

Outdoor rain and snow erosion or corrosive gases and media should be used anti-corrosion products.